Cutting tools, moulds

Since 2013, BETAR has been developing its own production and repair of cutting tools, molds, dies and other equipment, as well as metalworking. Our solutions allow to minimize the number of tools, and therefore the number of operations in the manufacture of products.

Since 2013, BETAR has been developing its own production and repair of cutting tools, molds, dies and other equipment, as well as metalworking. Our solutions allow to minimize the number of tools, and therefore the number of operations in the manufacture of products.

Our advantages

- Development and production of unique tools (designed for specific tasks)

- Convenient location ( for those who have been looking for suppliers of quality equipment within the Russian Federation)

- Fast delivery (in Russia within 2-7 days)

- The fastest possible production time (depends on the tool complexity and the workload of production)

- Our solutions allow you to increase production and reduce costs (minimum number of tools = reduced manufacturing operations)

- High-tech equipment of the world leaders in the engineering industry

- Service on favorable terms

In addition to the manufacture of molds, designed by our technicians we produce tools according to the customer’s drawings, we can help you to improve the performance and technical characteristics of existing molds

You can order standard tools or large molds up to 2 tons weight. They are applied in automotive industry, parts for household and construction use.

Cutting tool

Selection, design and manufacture of standard and non-standard cutting tools.

We offer:

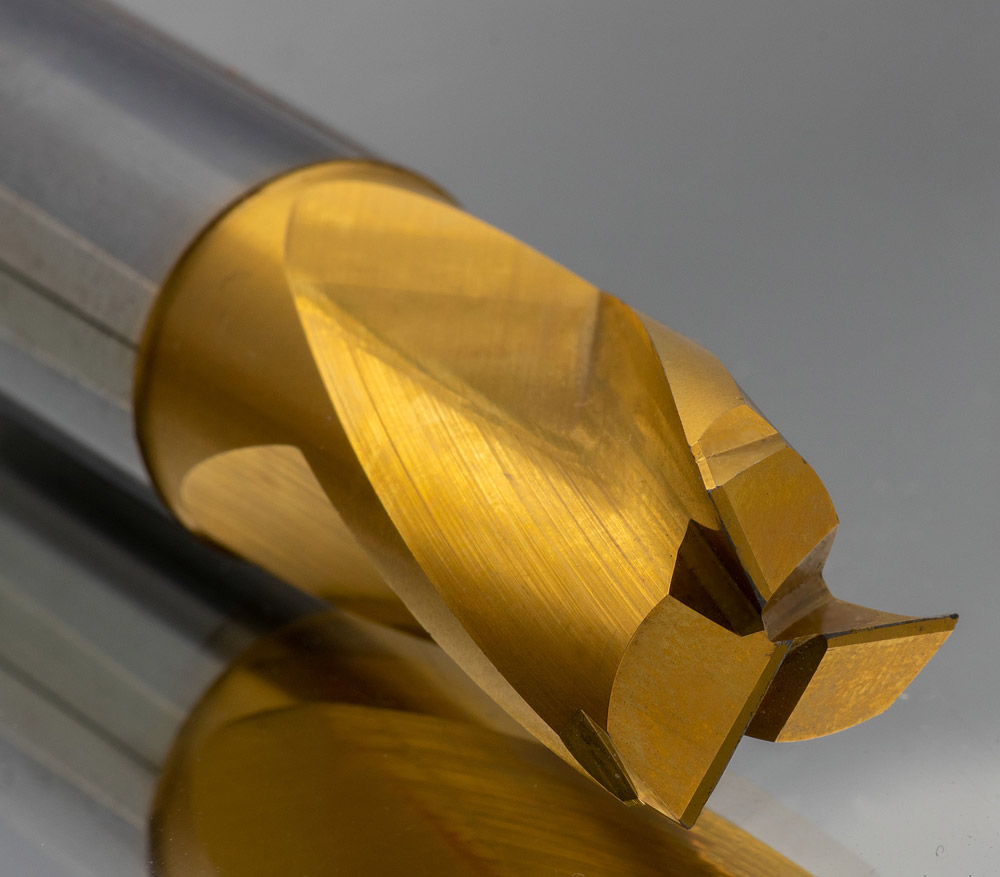

- Standard monolithic carbide end tools (roughing and finishing mills, drills, etc.)

- Non-standard monolithic carbide end tools (cutters with a complex profile, thread cutters, step drills, etc.)

- Tools with soldered carbide inserts with a maximum working diameter of 200 mm .

- Tools with cutting edges of polycrystalline diamond (PCD).

- To replace the existing profile tool with soldered plates on the tool with cutting inserts.

Design of tool

Tool for a wide range of processing tasks:

- A tool can be designed as a "from scratch" or modified from an existing one.

- A tool is designed with all the production features and customer requirements.

- Resource of holders is considerably larger than the resource of cutting inserts.

For tools used in the processing of non-ferrous metals, composite materials and wood we offer to implement into manufacturing some tools with locally soldered diamond plates to increase the durability of its cutting edges.

We can also design a cutting tool with replaceable standard plates, which will replace the existing complex tool with soldered plates. This will reduce tool costs by increasing the durability of the newly designed one and the need to change the cutting inserts only.

Manufacture

Standard axial monolithic tool — cutters, drills, reamers, alignment, engravers. Cutters can be for roughing and finishing of any kind of material, end-flat and spherical, with a radius on the tooth tops and chamfer. Length-standard, lengthened or shortened. Drills — with clockwise and counterclockwise rotation, standard and elongated.

Custom monolithic tools — step drills (multistage, profile) profile cutter (to handle special grooves, ridges and pockets), threads (for any kind of them — metric, inch, thrust, etc., with any standard and non-standard step, single - and multiple-start for internal and external threads)

Profile tool with soldered carbide plates (for processing non-ferrous metals and wood)

Profile tool with soldered diamond plates (for processing of non-ferrous metals, wood and composite material, the plates can be soldered both on the entire cutting edge and locally)

Turning tools with soldered plates (any standard and non-standard tools)

Non-standard profile tool with standard cutting inserts (DIN and ISO plates)

Manufacturing of the customer’s tool according to his drawings and samples (we work both on 3D models, and on flat drawings)

The monolithic tool regrinding and re-sharpening/repair tools with brazed plates both our production and produced by third-party manufacturers, thanks to the re-sharpening can increase the tool life several times; recovery tool allows you to use the holder multiple times, thanks to resolder of the carbide inserts.

- To increase the life and performance of the tool cutting edges can be applied the reinforcing coating depending on the kind of processed material.

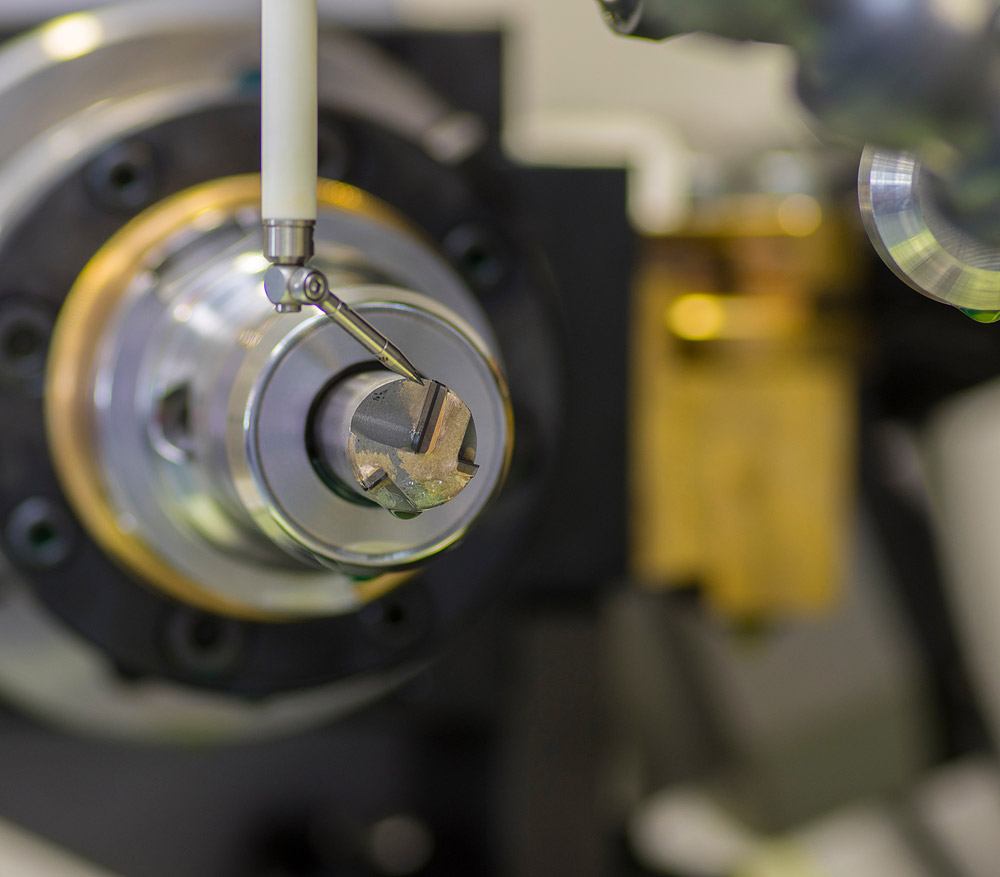

- All equipment available in MCC BETAR Ltd., allows to produce high precision and high quality cutting tools with accuracy up to 6 kvalitet (grades of accuracy).

- Optional equipment allows to control the quality of manufactured tooling.

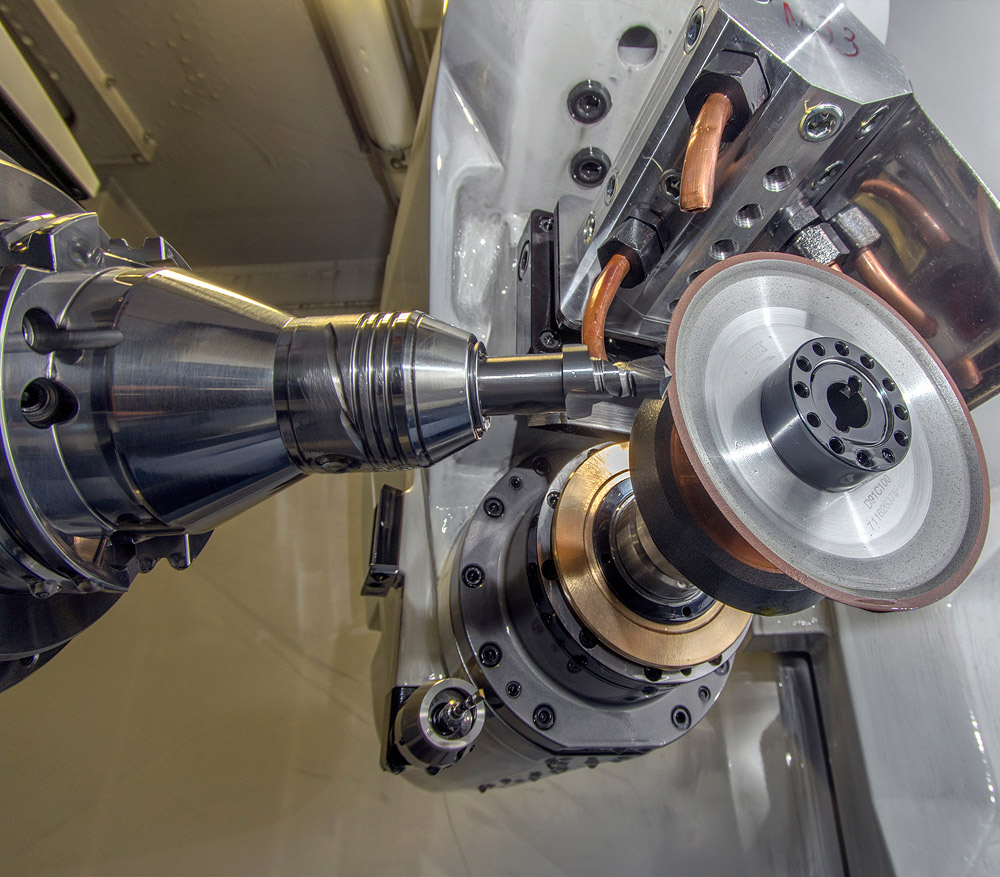

- We use high-tech equipment of world leaders in the engineering industry, such as DMG, Sodick, Ferrari, ANKA, Vollmer.

- Thanks to the Zoller measuring complex, each produced tool is complex tested for accuracy, and then receives a passport with all the necessary technical characteristics, which confirm the quality and compliance with instrument specifications.

Design in a modern CAD system Kompas 3D, Siemens Solid Edge, Solid Works. design in CAD systems (Compass 3D and Siemens Solid Edge). Due to the built-in computer-aided design systems, the DATA allow to obtain the preliminary design of the mold and its cost within 2 days. Our specialists have experience in tooling design for parts with both rough tolerances and high-precision dimensions.

The available CAM-system NX CAM-Express allows us to prepare a complete manufacturing process for almost any product, taking into account the time of manufacture and the quality of the treated surfaces. Besides the parts manufacturing technology designed by our stuff , we can also provide services in preparation of the manufacturing process of parts required by third-parties for 3d models and drawings, including all requirements and wishes of the customer, both to cutting tools and auxiliary equipment. We can offer a technology with a full selection of tools and equipment, based on the capabilities of the processing equipment as well.

Productivity

per yearstandard monolithic tools

per yeardiamond tools

per yearspecialized tool

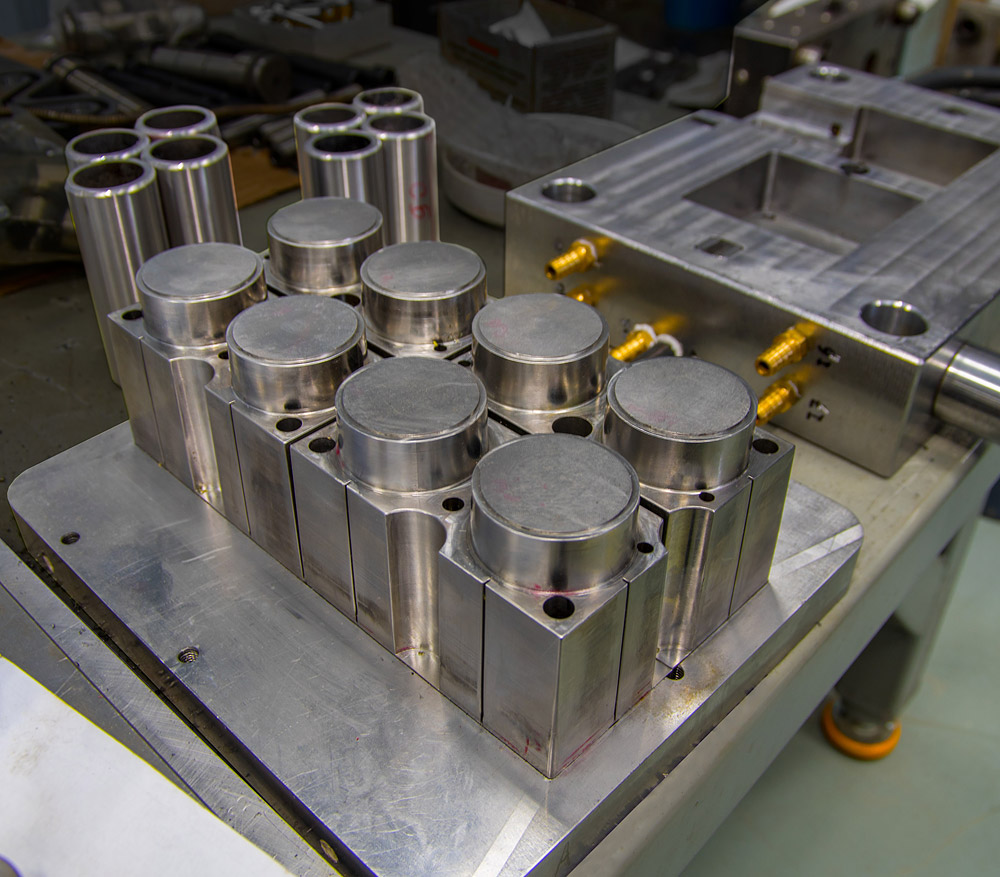

Injection Molds

Selection, design, manufacture and maintenance of molds

- The mold design is made in a modern CAD/CAM systems Solid Edge and Compass 3D, using databases of standardized elements of HASCO, Fodesco, FCPK.

- We use high-tech equipment of world leaders in the engineering industry (DMG, Sodick, Ferrari)

- Interoperable control interoperational control and control of finished products end-item inspection is carried out thanks to modern systems of measurement and control, including integrated in the equipment.

- Quotation is offered in 3-7 days

- Manufacturing of equipment according to customer's drawings

- Recommendations for improving operational and technical characteristics of existing available molds.

- Maintenance and repair of molds

The mold with the cold runner gating system

The mold where heating of polymers in the gating channel is not provided, and therefore the gating cools down together with the cast parts. When opening the mold frozen system “product-gate” drops out.

Mold with hot runner gating system

Heating and maintaining of the required melt temperature inside the mold is provided by special electric heaters. Special temperature controllers are used in the Gating system. When opening the mold, the frozen product drops out. The absence of gates eliminates the cost of their storage, processing and disposal, as well as significantly reduces the production cycle of the product item.

Molds for casting parts with embedded elements

This type is used in the following cases:

- the finished part should have a thread that would be durable under constant loads, and the quality of the threaded element should allow the frequent disassembly of components;

- small tolerances for the internal thread elements should be ensured;

- a secure fit of the high-loaded element on another loaded element, for example, when installing a plastic gear on the axle should be done

- an electrical circuit must be provided.

The main feature of injection molding with embedded metal part is the integration of casting and assembly processes.

Molds with replaceable cassettes

Removable plate molds are efficient in reducing production cost of mold base and increasing performance by layout of a variety of the similar products cassettes on the same block mold.

Metal fabrication services

Using the available modern metalworking equipment we can make the following types of works:

- Milling and drilling of all kinds of metal, plastic, composite materials on universal equipment and modern high-performance and high-precision CNC machining centers. 3, 4 and 5-axis processing. Maximum dimensions of processed items - up to 3200 mm.

- Turning on both universal and CNC machines. We have a long turning automatic lathe for serial production of parts. Machining with a drive tool for additional milling and engraving operations. The maximum dimensions of workpieces are Ø400х400 mm.

- Electrical discharge machining (wire-cut and die sinking) — machining of any conductive and superhard materials with high accuracy. It is used for the manufacture of high-precision forming parts with high requirements for surface roughness.

- Circular and flat grinding -semi-finishing and finishing of parts surfaces. The maximum dimensions of workpieces for round parts are Ø250х400, flat — 500х1000.

- Repair of parts by micro-welding, which does not change the structure of the material around the treatment area. Grinding and polishing on ultrasonic installation.

- Heat treatment. A lot of steel types can be heat treated due to mordern furnaces. The maximum dimensions of the heat treatable workpieces are 600х600х400.

Types of works: heat hardening, carburizing, annealing, tempering.

Service maintenance of cutting tools

We offer regrinding of cutting tools manufactured by our firm, as well as any other manufacturer.

The service of molds includes:

- inspection

- maintenance, in accordance with the passport for the equipment

- restoring of tooling

- follow-up

The cost of work is determined after the damage detection of tools.

Additional service

Planned, unplanned, overhaul of any equipment of other manufacturers.